GURKI shrink packaging machines deliver an excellent combination of price, versatility and customer support. With a comprehensive line of durable shrink wrapping machines, we offer the packaging solution you require and deliver the value you seek.

Customized to your needs • Individual and flexible.

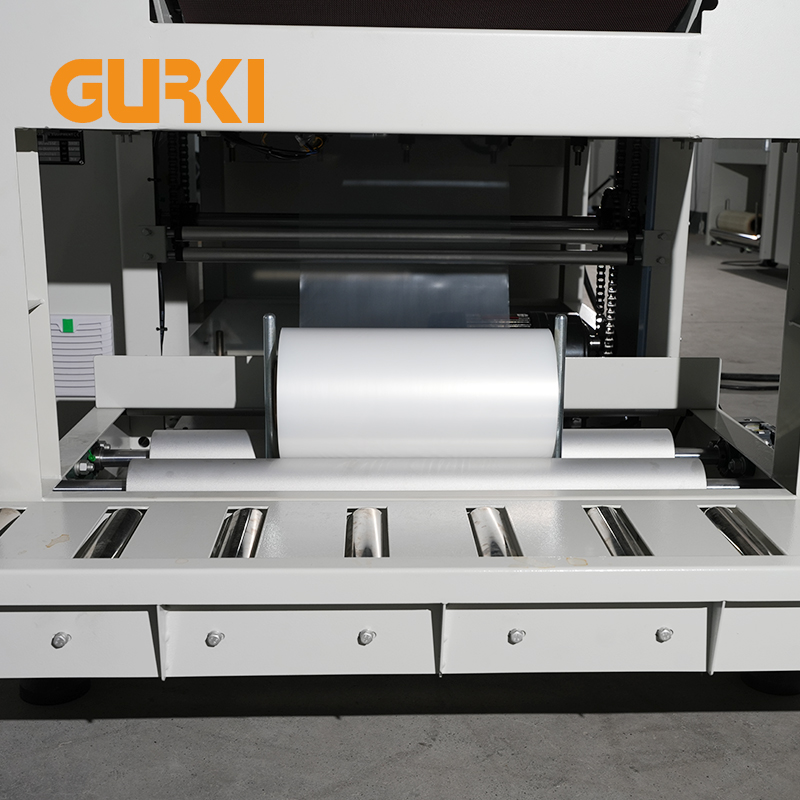

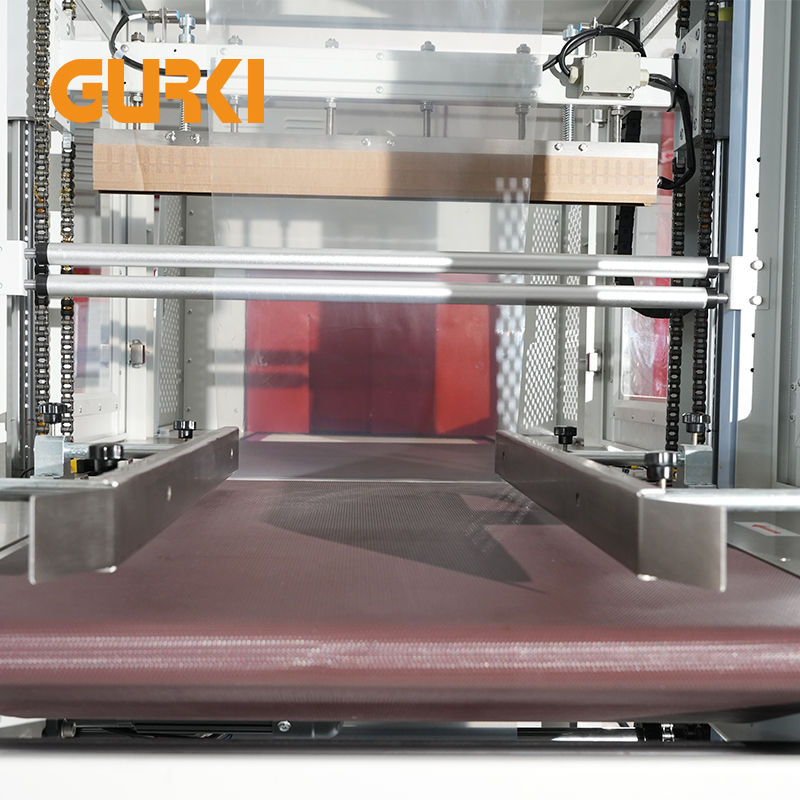

From l-bar sealers to high-speed automatic shrink packaging systems, GURKI offers a wide range of shrink packaging machines. This enables us to fit the right mix of features and options to suit any customer’s production needs.

Here are some things you can expect:

·A review of your current packaging processes and suggestions for improvements.

·A plan for how to right-size machine platforms for speed and complexity to match your current—and future—production demands.

·Examples of how packaging automation was successfully implemented in businesses similar to yours.

·Suggestions for new packaging equipment that will dramatically increase productivity and efficiencies.